+7 (905) 654 69-41ЧатЗаказать звонок

М Е Г АТ Е Х

г. Воронеж, ул. Кольцовская, д. 58А

Промышленные машины

О компании

An important sector for Megatech OOO is the construction of new machines. We design and supply in-line or reel-to-reel printing machines for plastics or paper materials. Hot embossing and cold embossing machine for plastics and paper, automatic paper, aluminum, and plastic coilers and unwinding machines, as well as special machines like inspection machines for printed materials and plos Fol Fold for liars are all part of our product range.

Flexographic printing "STACK TYPE"

Winders and decoilers

Embossing machines

Special lines

О компании

Relying on a reliable partner, who with impartiality and competency can provide a technical evaluation of the proposals relating to any line used, reviewing them and, if necessary, testing them becomes crucial to correctly deciding on the plant to be acquired, but it often is not enough to implement and improve its production capabilities. OOO Megateh, in addition to providing a technical opinion about the suitability of a used plant, can handle all those operations crucial for its proper transfer, guaranteeing a successful outcome of the project

О компании

During the transfer of entire plants, Megatech provides customers with experience and skills acquired, providing them with the necessary advice for defining the necessary positions, spaces, and production flows in their internal plants to optimize and streamline complex operations that must take into account various aspects and components. During this delicate process, we take care of the installation and commissioning of the lines, relieving customers of organizational burdens and series of commitments, which could distract them from the daily operation of their company.

О компании

In addition, thanks to our qualified team, cutting-edge equipment, and twenty years of experience in this sector, OOO Megatech provides support for the installation of new facilities for important manufacturers in the converting industry. The correctness and transparency we have always been known for allow us to provide installation services for companies in the same industry without ever compromising confidentiality, allowing us to propose ourselves as a serious, reliable, and punctual partner to any company seeking external support for installations. The organization of all necessary phases, attention to detail, and procedures tested and optimized over the years allow OOO MegaTech to complete each project professionally and within the required deadlines, costs, and results.

Этапы

TEST

Старт: 1 сентября

Утренние часы

This phase is necessary for evaluating and establishing, through a documented report produced by one of our representatives, the actual condition of the pipeline before the transfer. The pipeline to be transferred is tested in its essential parts to highlight any complexities.

DISASSEMBLY

Старт: 1 декабря

Дневные часы

Our specialized technicians, who all have many years of experience in this sector, take care to mechanically disassemble and electrically disconnect the line, making it suitable for loading onto transport vehicles or into containers. They also mark and photograph cables and components.

PACK

Старт: 1 апреля

Свободные часы

We are organized to directly supply materials and specialist in the rizza of components on platforms, pallets, or in crates. We also collaborate with companies responsible for the supply of these packages in order to optimise and economise the construction by providing the same dimensions and weights as what must be transported

HANDLING

Старт: 1 апреля

Свободные часы

We take care of loading onto trucks or into containers, and unloading at installation sites. If required, we can provide lifting equipment directly or technically support external handling companies (our technicians have certificates for operating trucks and aerial platforms, and are qualified to work at height).

TRANSPORT

Старт: 1 апреля

Свободные часы

Being able to rely on serious freight forwarders and competitive carriers often determines the difference between good and excellent success for a project. By now, we have worked in more than forty countries around the world and are organized to handle this aspect, having the opportunity to follow and monitor this important component with reliable and punctual forwarders and carriers.

INSTALLATION

Старт: 1 апреля

Свободные часы

A fundamental condition to minimizing the probability of errors or loss of time is that the technicians involved in the dismantling phases are the same as those who will be responsible for the installation, taking full advantage of work done in previous phases.

FINAL TESTS

Старт: 1 апреля

Свободные часы

At the end of installation, our technicians perform tests again that were performed before disassembly of the line. This phase is crucial in order to proceed with commissioning the line, thus guaranteeing the final result for our customer. Often, some small problems that were identified in preliminary tests are solved during installation without changing commercial agreements.

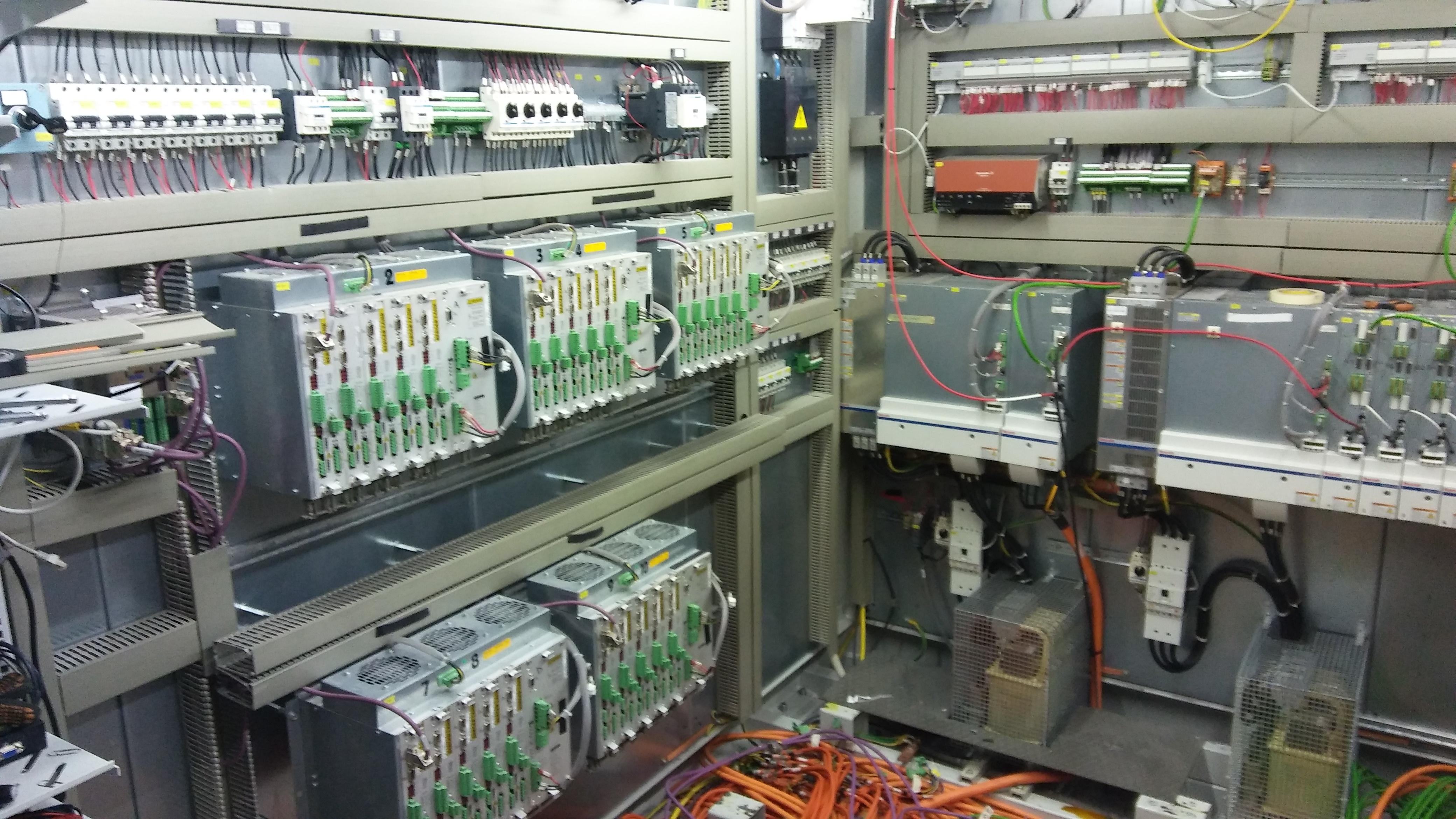

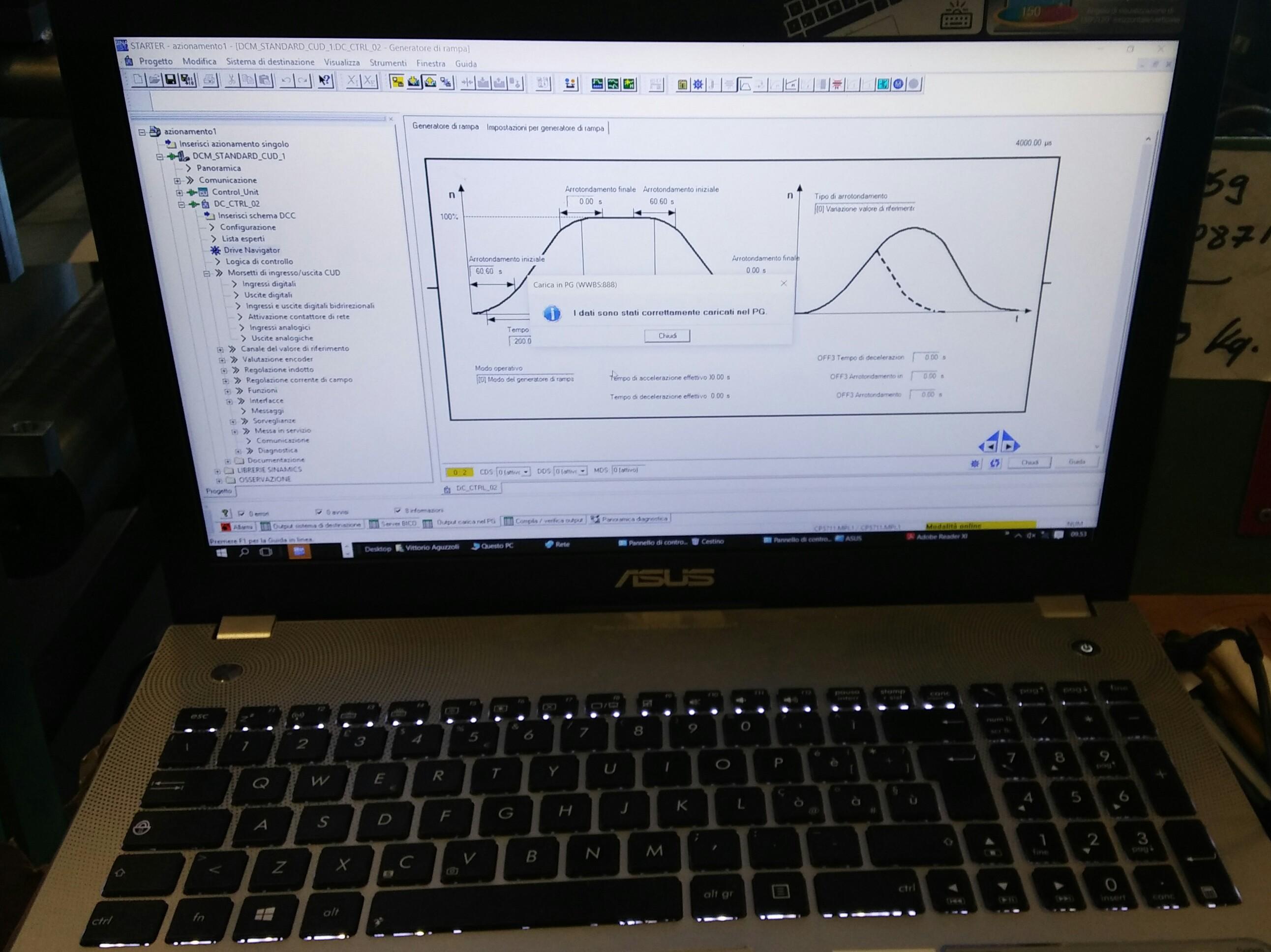

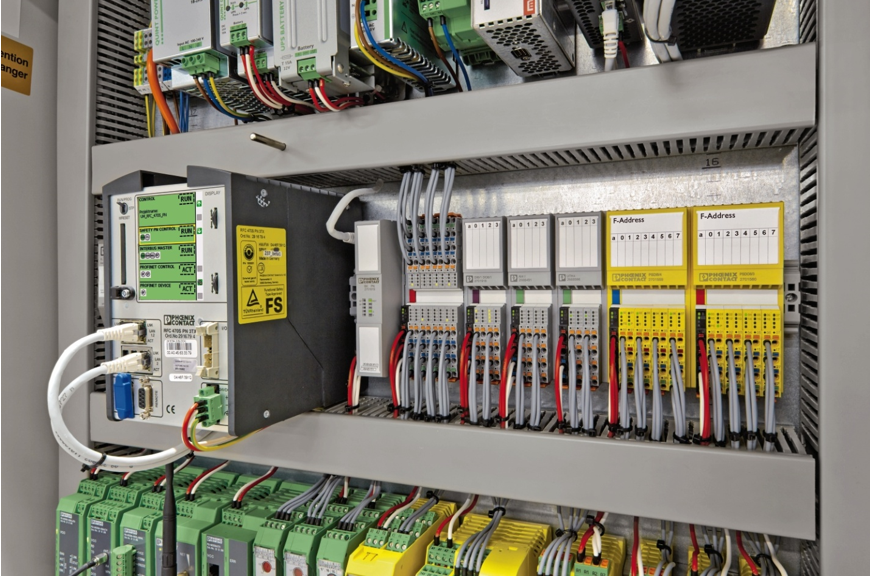

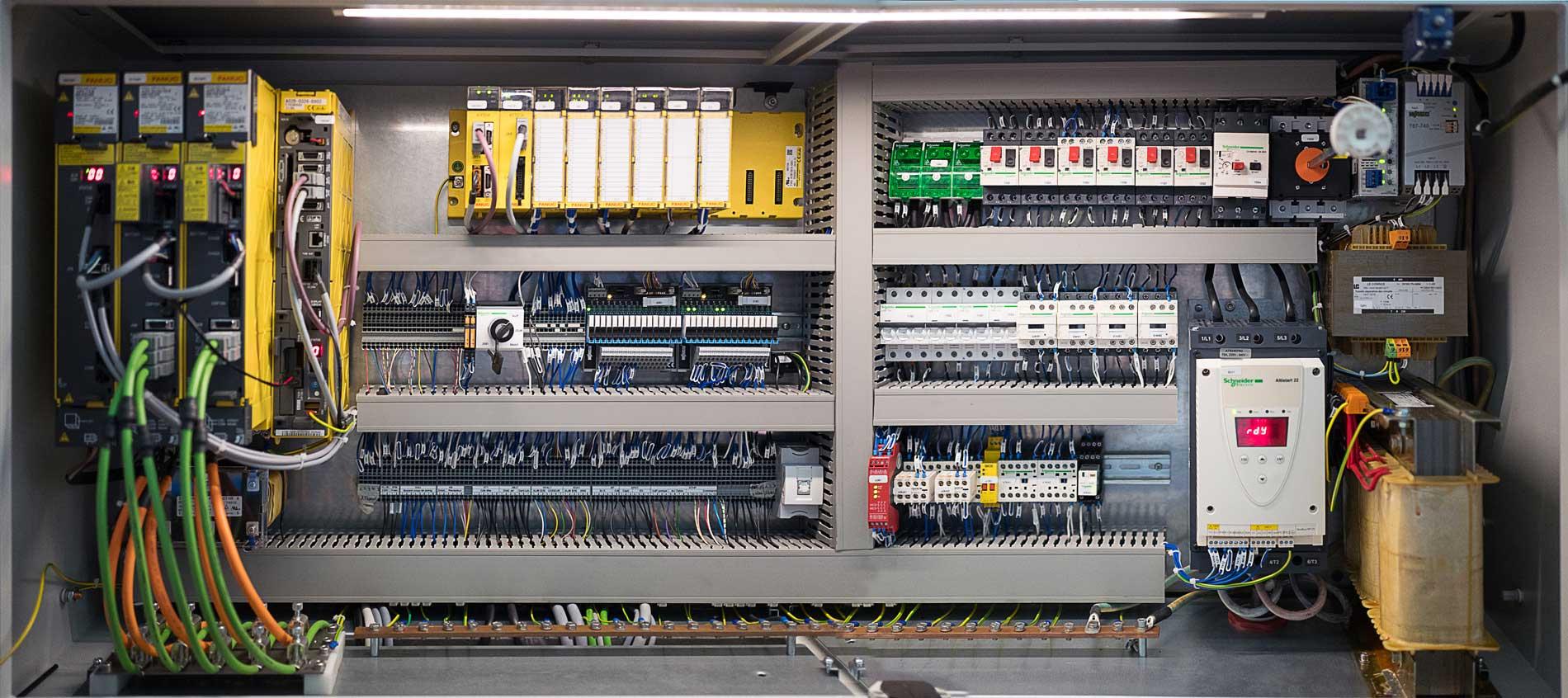

At "MEGATECH", we believe that quick and focused assistance to our Customers is synonymous with efficiency and reliability, and therefore we are better organized to provide electronic and mechanical assistance directly on our Customers' production sites. In case the Customer's needs require more complex or drastic measures, we have a specialized site with an area of 1000 square meters, which is structured and organized to accommodate complex and bulky production lines. We also provide electronic and software services in Siemens and Rockwell systems, replace electrical components of any brand, and supply mechanical spare parts to replace worn or damaged components.

О компании

Technical maintenance

Prevention is better than treatment, and therefore we propose and provide periodic maintenance programs, structured and coordinated according to the production lines present in the relevant companies, and adapted to the needs of the Client. We organize maintenance periods in full synergy with the production department, fully optimizing production processes, avoiding technical downtime.

О компании

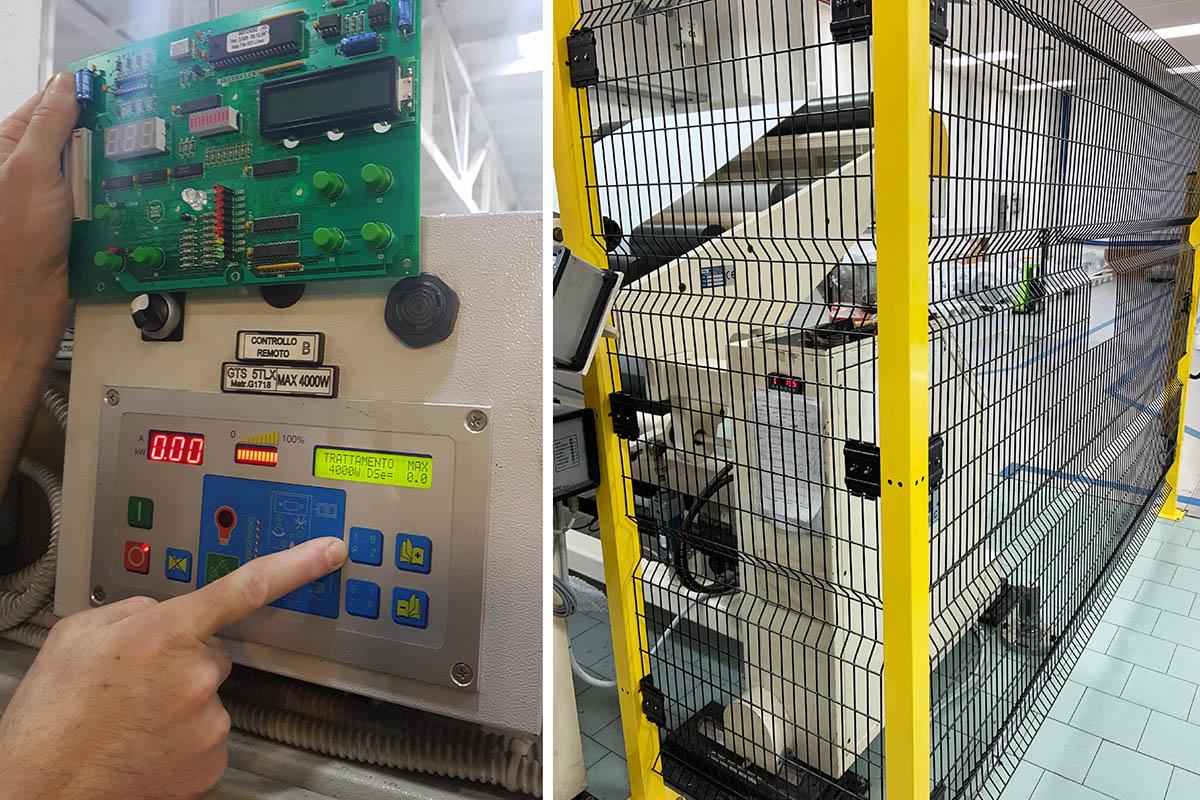

Updates

Replacement of quality control systems, installation of voltage regulation systems, selection of motors and drives with more efficient components of the latest generation, installation of cutting or edging units, replacement of components that are currently unavailable on the market: these are some of the operations that our specialists are most often called upon to perform. Our goal is to improve and optimize the performance and quality of legacy lines in the interest of increasing Customer efficiency and productivity.

О компании

Repair service

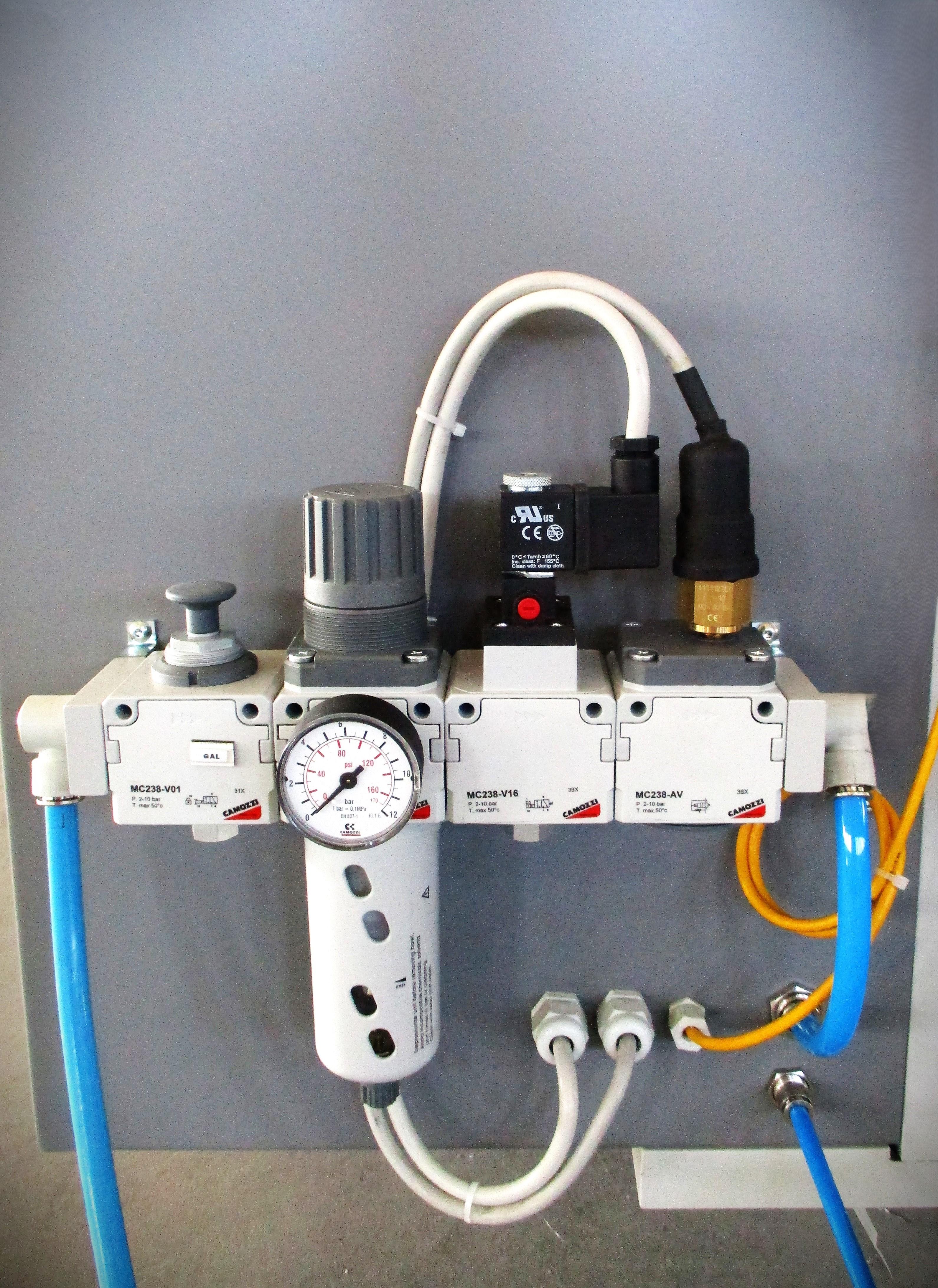

The repair of an electrical, hydraulic or pneumatic system, the replacement of damaged or unavailable commercial components, the repair of worn-out mechanical parts, the conversion of a heating source from electric to gas or vice versa, the replacement of gaskets or equipment outside the line are just some of the operations that can be included in the overhaul of the production line, and which we can provide in accordance with with more or less radical interventions. In all the contexts of this, we proceed to develop a repair project with benefits for the benefit of the Client.

О компании

Adjustments

We believe that safe operation is an important principle, for this reason we are engaged in adapting to the existing safety standards of outdated lines by supplying or replacing fixed fences, mobile fences, micro-security systems, producing operation and maintenance manuals, inserting pictographs or solar cell safety systems and much more. After the inspection, we formulate a clear, simple and transparent assessment aimed at the safe placement of the equipment and related production cycles, without prejudice to their further use.

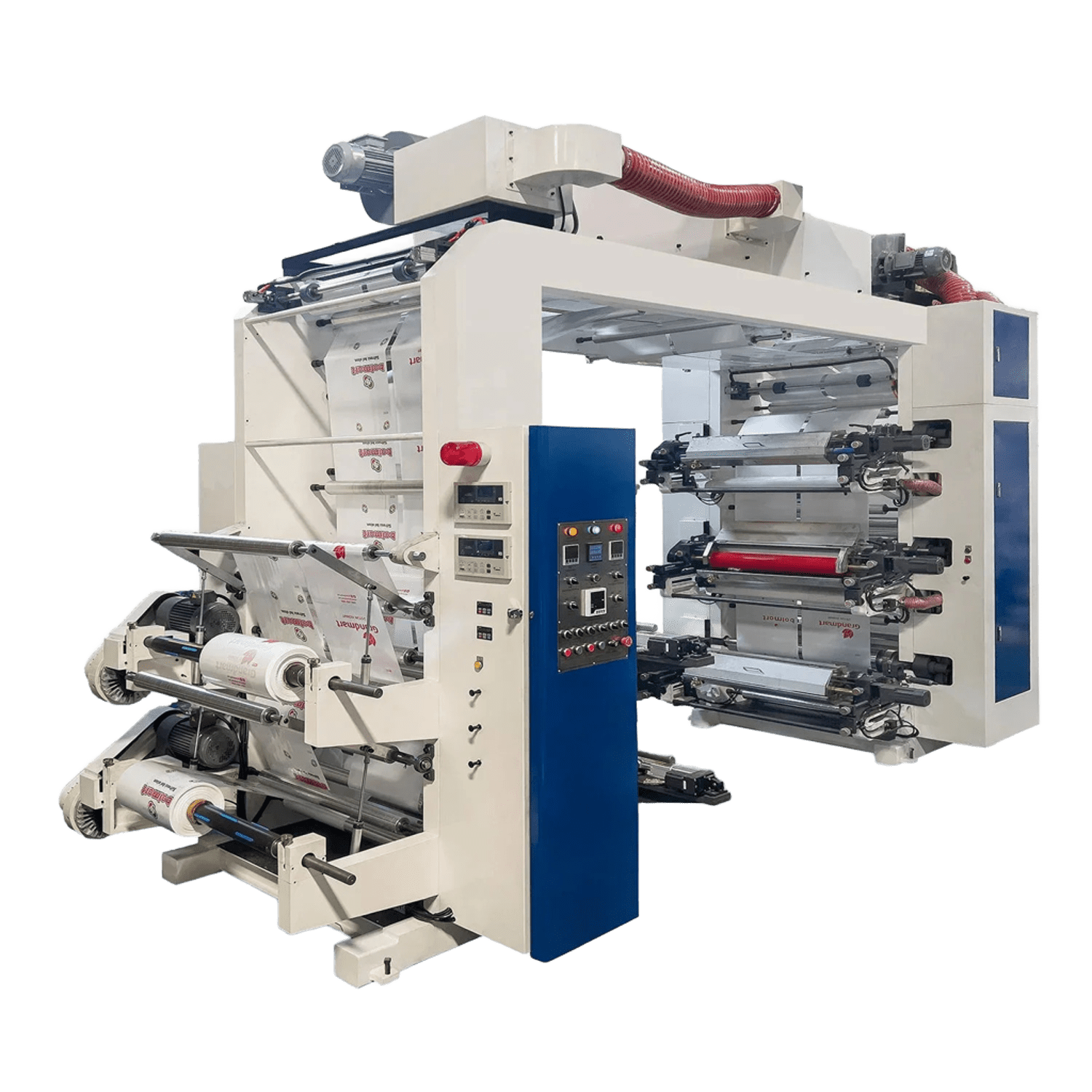

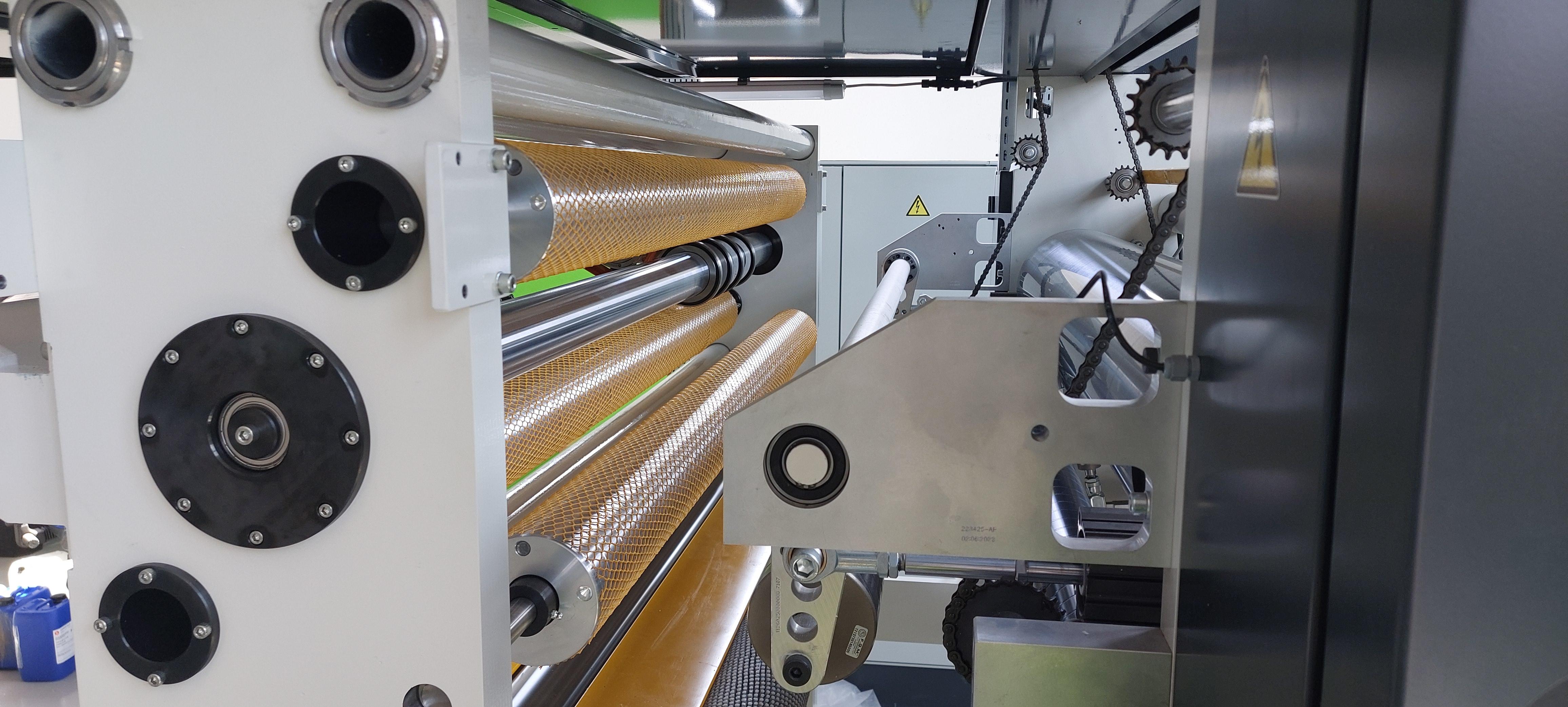

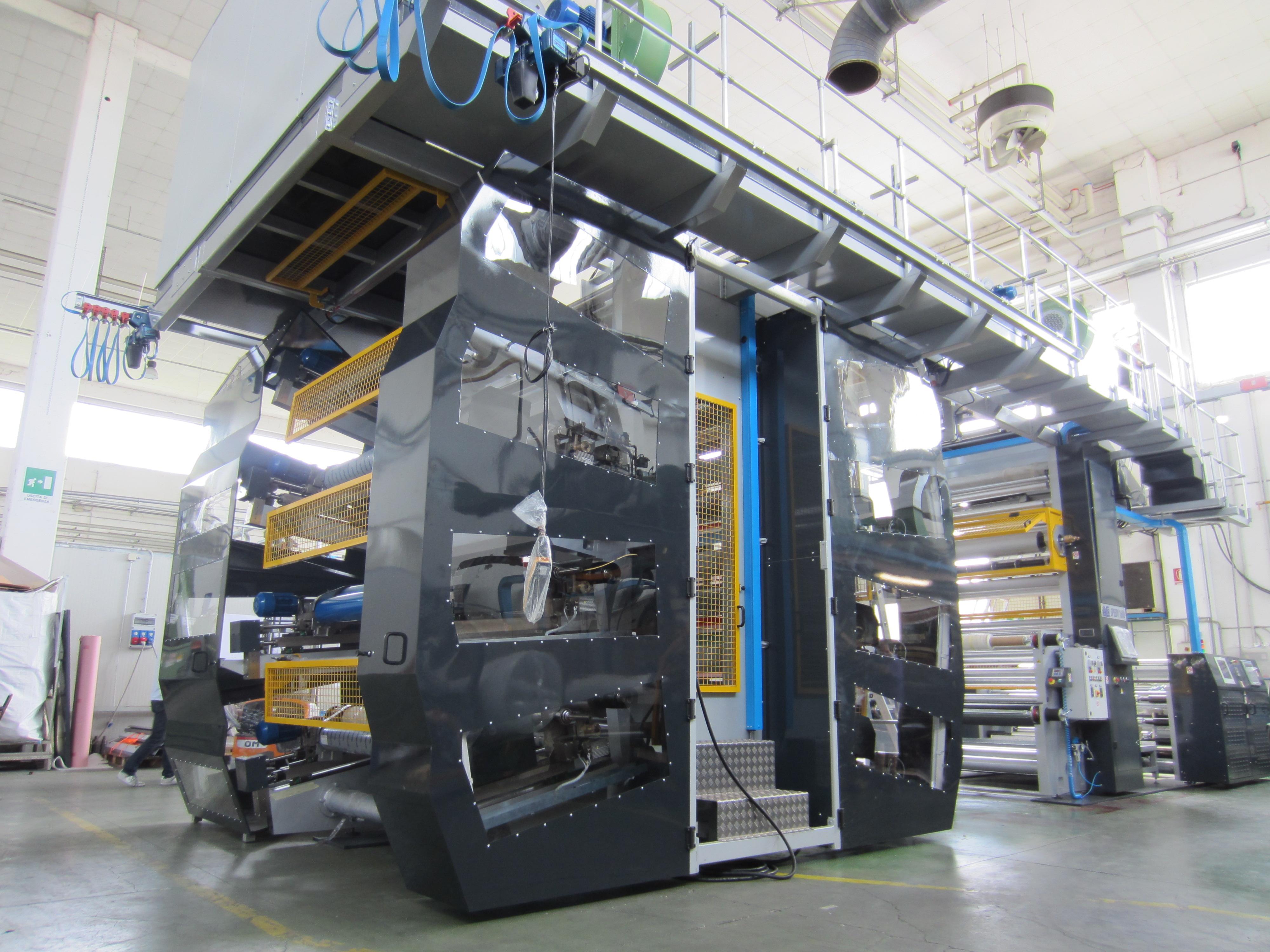

Flexographic printing "STACK TYPE"

Functionality and quality are guidelines for the design and manufacture of our "Stack Type" printing machines, from coil to coil or for installation in line, for bubble wrap extrusion machines, for paper bags, or for plastic bag welding machines. They are offered with two, four, six or eight print groups, and they differ significantly for the two types of ink tanks. The "SPEEDY" model is the latest version and comes complete with independent motorized feeds on both sides of the holder axis and the anilox axis, motorized ink crushing, motorized printing pressure using a portable device, inkwell movement using ball screws, as well as a squeegee, and independent counter-printing motorization.The simplest version is represented by the "STURDY" model, which, while maintaining the same concept of strength, is equipped with manual or motorized feeds, but with a single motor, manual pressure control, inkwell lock, hydraulic booster printing input and output, rubberized cylinder ink, hydraulic ink grinding, single motor motorization.If necessary, it is possible to print the front and back sides of the processed material. Useful print strips range from 800 mm to 1600 mm with a minimum print size of 350 mm and a maximum print size of 1000 mm (depending on the width of the print, the minimum size tends to increase).The machines can be installed with gas or electric battery drying systems, squeegee assemblies, trimming or cutting systems, and changing hoses. In the coil-to-coil version, single, overlapped, or automatic turret windings (revolver winding systems) can be installed, suitable for coils from 800 mm to 1200 mm in diameter.

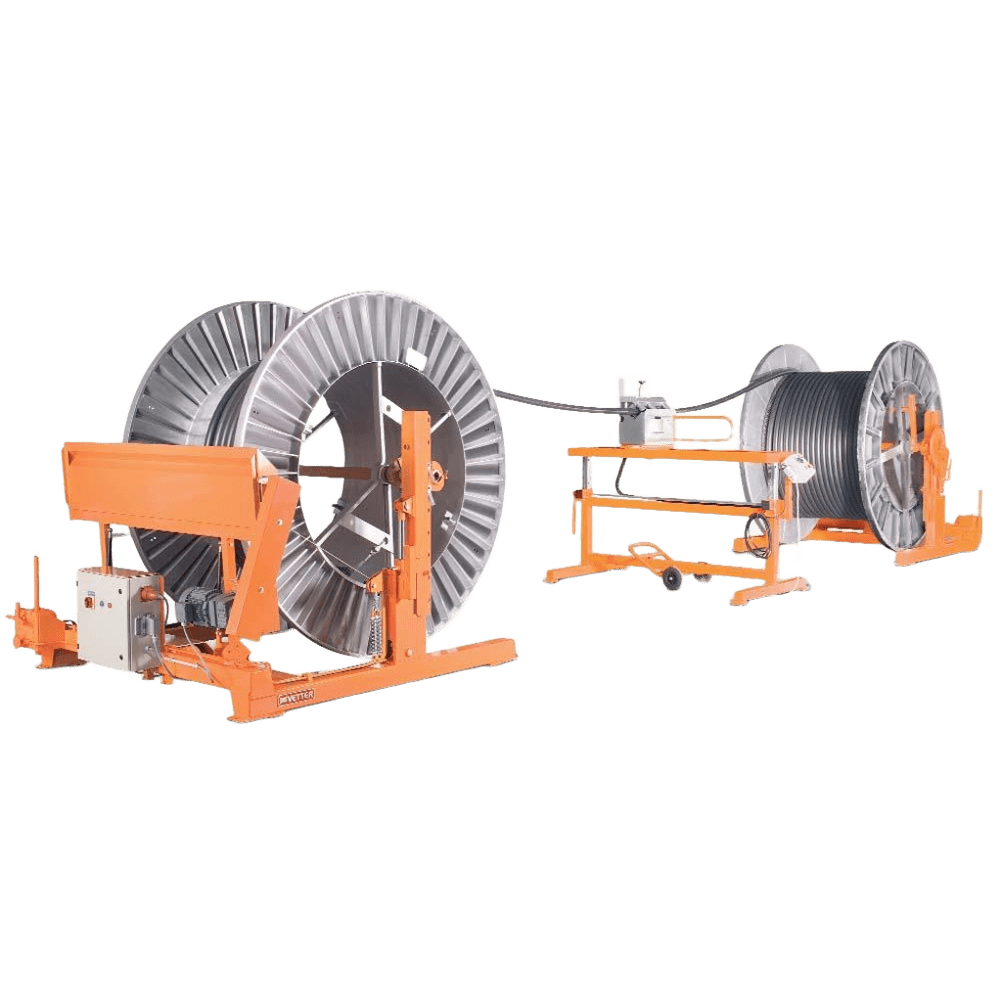

Winders and decoilers

Material management at the initial and final stages of the production process is essential to obtain a high-quality finished product. For this reason, MEGATECH LLC provides reliable machines for manufacturing and packaging, with really important production characteristics, high quality and very attractive prices. Our machines, depending on the "WOLF" or "LIZ" model and the required characteristics, can unwrap and wrap paper, stretchable or semi-rigid plastics, aluminum, and in combination with various densities and thicknesses, and are characterized by robust structures, small dimensions, and the use of advanced technologies and systems. The various models are ideal for the required ranges and range from a minimum of 300 mm to a maximum of 1600 mm, can accommodate coils up to 1200 mm in diameter.; They can be single-bar, double-overlap or automatic turrets, and all of them are equipped with tension control and adjustment using load cells or pneumatic dancers with direct control from the operator panel. We offer the latest generation of motors with AC motors driven by the latest drives, which significantly save energy. At the Customer's request, pneumatic or magnetic brakes can be installed for some models of the decoiler. The horizontal cutting system and gearbox control with load cells have made our LIZ revolver winders and WOLF revolver unwinders with automatic transmission, which is essential for some Customers working in the field of medical aluminum packaging.

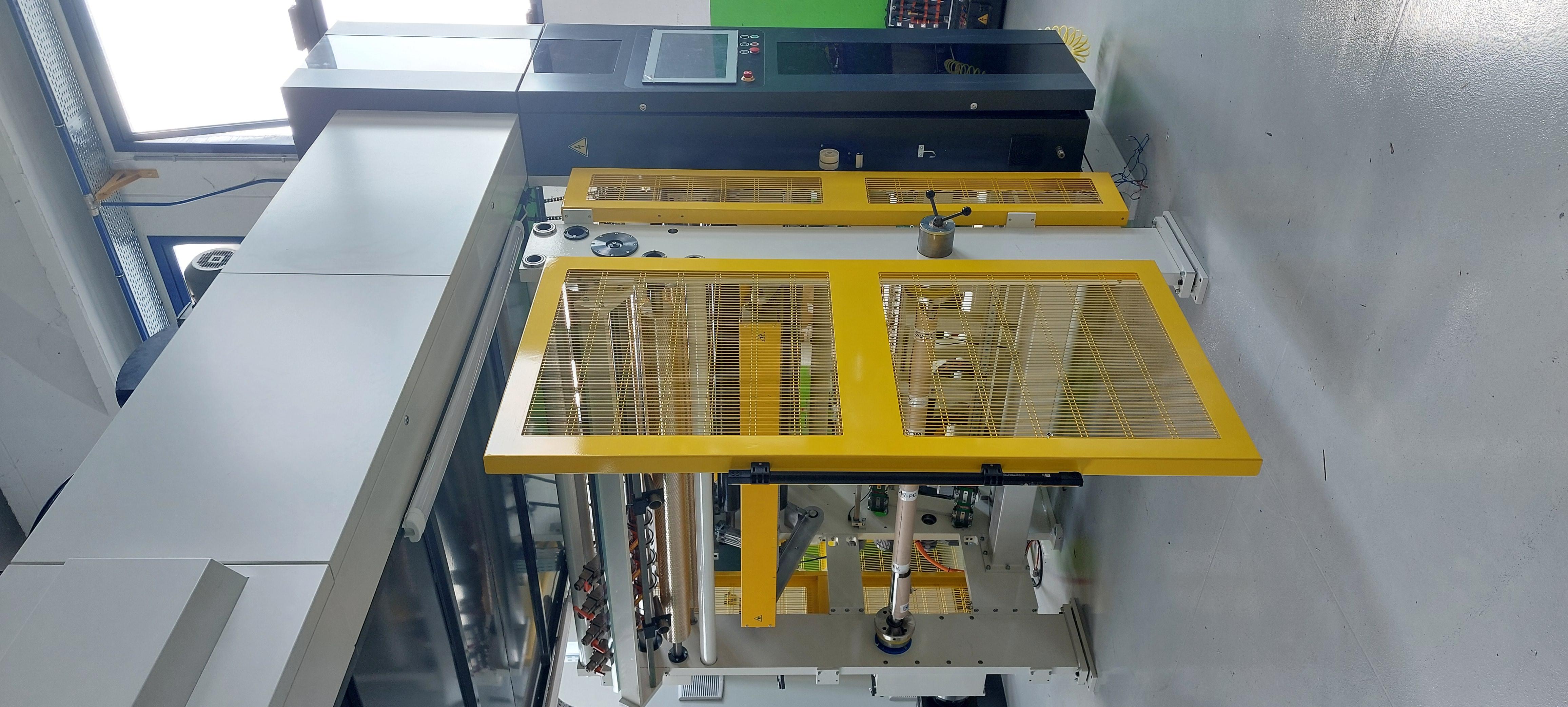

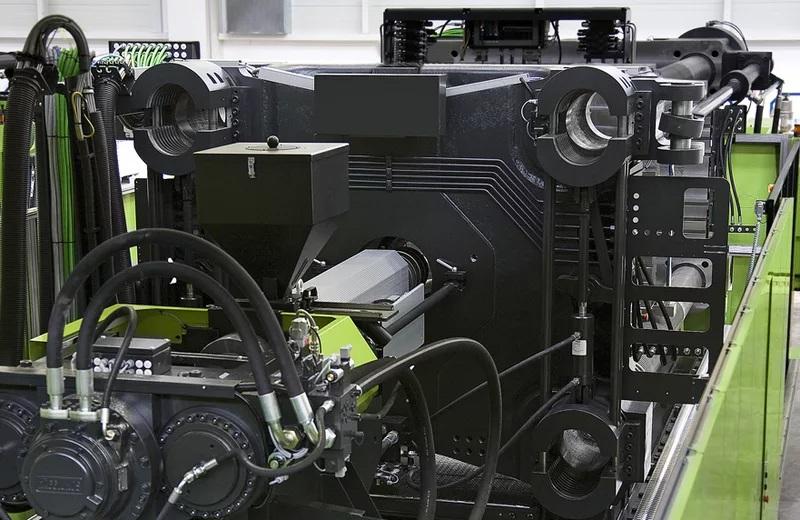

Embossing machines

Increasingly, the surface of materials present in the conversion or packaging sector is being modified to use these films in specific applications or simply to add value to a product, and embossing processing is the most striking example of this. MEGATECH LLC provides reliable embossing machines designed for hot or cold stamping of various materials. Our "Stone" embossing machines can be installed on existing lines or complete with a decoiler and a coiler.; They can emboss paper, semi-rigid plastics, aluminum, and in combination with various densities and thicknesses, and are characterized by robust structures, small size, and the use of state-of-the-art technologies and control systems. The suggested width ranges from a minimum of 800 mm to a maximum of 1500 mm, and if equipped with a decoiler and a winder, they can accommodate coils up to 1200 mm in diameter.The engraved roller and the back pressure roller can be heated or cooled depending on the material to be embossed. The back pressure roller can be of three types: steel (etched or smooth), wool paper, or rubber; the choice regarding the type of roller used is determined by the design of the embossing and, of course, the type of material you need to work with. The servo-operated system allows for optimal movement and adjustment of the two embossing rollers, allowing for multiple and precise changes in the depth of the embossing. The transmission is provided by a single gear motor, allowing for perfect synchronization of the embossing design, in the case of engraved back pressure or wool paper.

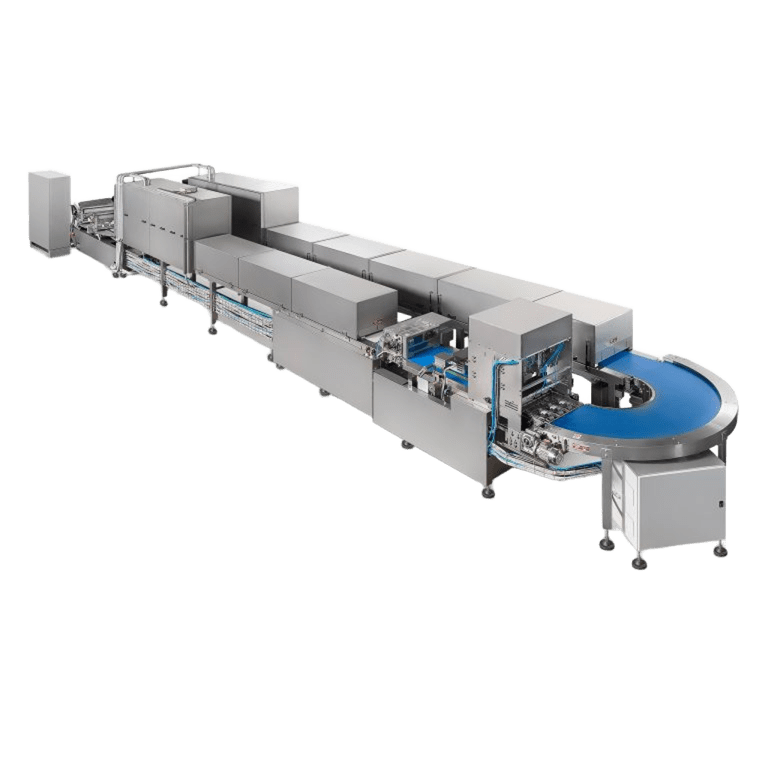

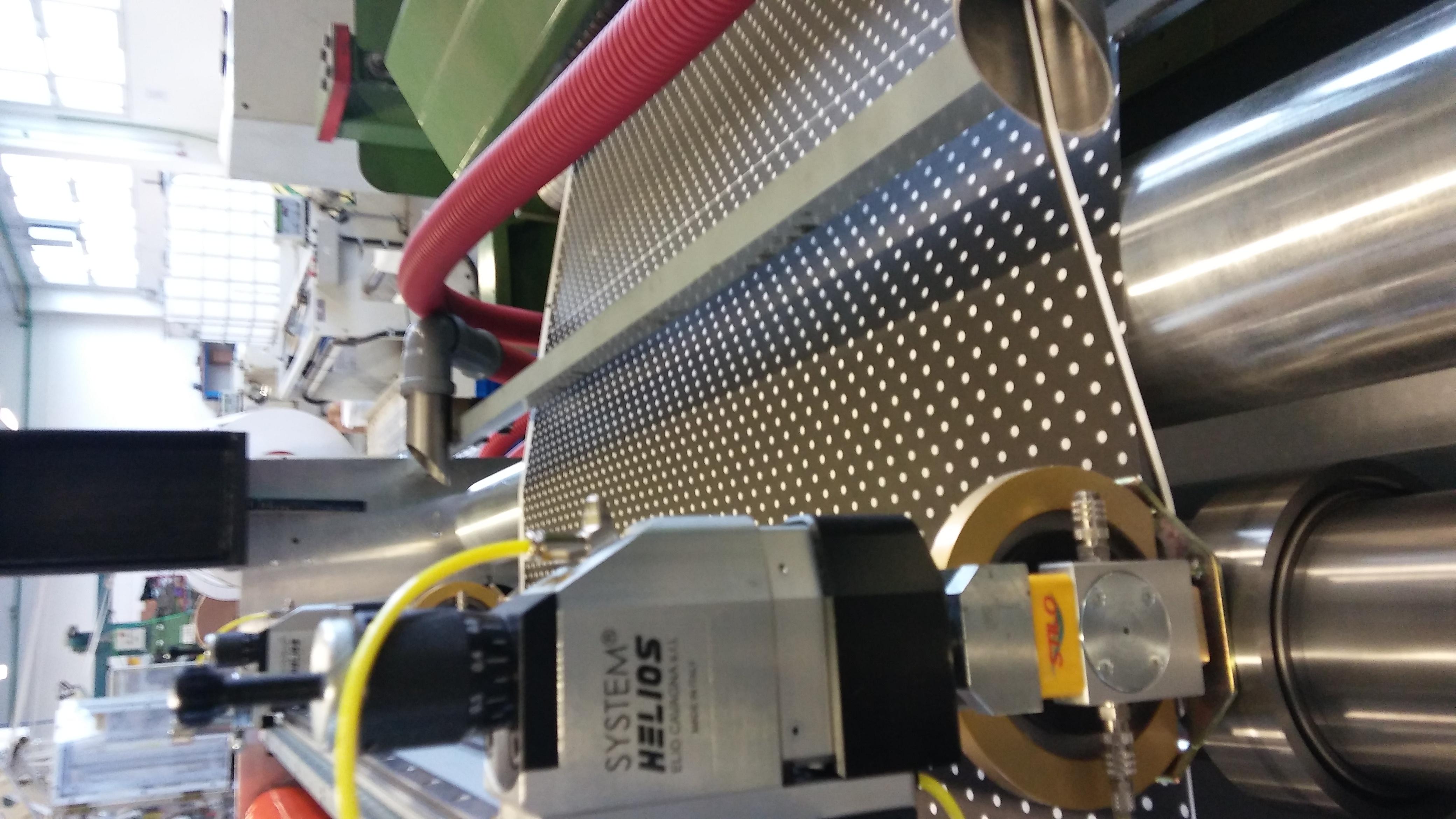

Special lines

The ability to rely on a reliable partner who provides the Client with the experience and resources gained over the years is necessary to meet the production needs that all large companies have to face every day. The Convert Service S. R.L. team will be happy to evaluate and explore the most effective and convenient solution for you to meet all your needs.Some partnerships with historical clients have made it possible to implement particularly successful installations. "Plow Folder" is a line designed and manufactured to fold and wrap sanitary products (medical and pharmaceutical) printed on paper in a spool. This method is easy to use and configure for various production needs, it is very functional and easy to control by the operator. The "Plow Folder" REMEDY models are available complete with one, two or three folding stations and are equipped with automatic cantilever winders for lateral unloading of coils with curved material. The working speed is 300 MT/min, and the width of the material can vary from 100 to 600 mm.Another very interesting product, it is presented by the inspector of the "RIBO" model, designed and manufactured to meet the increasingly urgent needs for defect-free materials that can accommodate any material inspection system to detect defects or errors present in the films. Our production line is equipped with a controlled automatic material extraction system that allows the operator to remove unsuitable product by simply selecting a setting on the panel. This control line is small in size and operates at a speed of 500 MT/min with a material flow rate that can range from 200 mm to 1300 mm.

Services

Identification of problems and prompt intervention to eliminate them are fundamental and necessary conditions for minimizing the negative impact of equipment downtime, but they alone are not enough to optimize the efficiency of production facilities, for this reason MEGATECH LLC is also organized to provide routine or emergency maintenance services, which reduces the risk of unforeseen events and the likelihood of equipment downtime.. If necessary, MEGATECH LLC can offer substantial interventions (repairs) aimed at optimizing the efficiency of the equipment, adapting it, among other things, to current safety standards. In a simple and understandable way, after the necessary inspection, we, together with the Client, evaluate the feasibility, advantages and costs that certain operations may entail. The professionalism of our team is aimed at meeting the most important needs of our Clients; We can provide staff with many years of experience working with printing machines, welding machines, plastic film extruders, embossing machines, as well as electronic and electrical systems and mechanical maintenance.

Order a call